Commercial Vehicle Air Disc Brakes

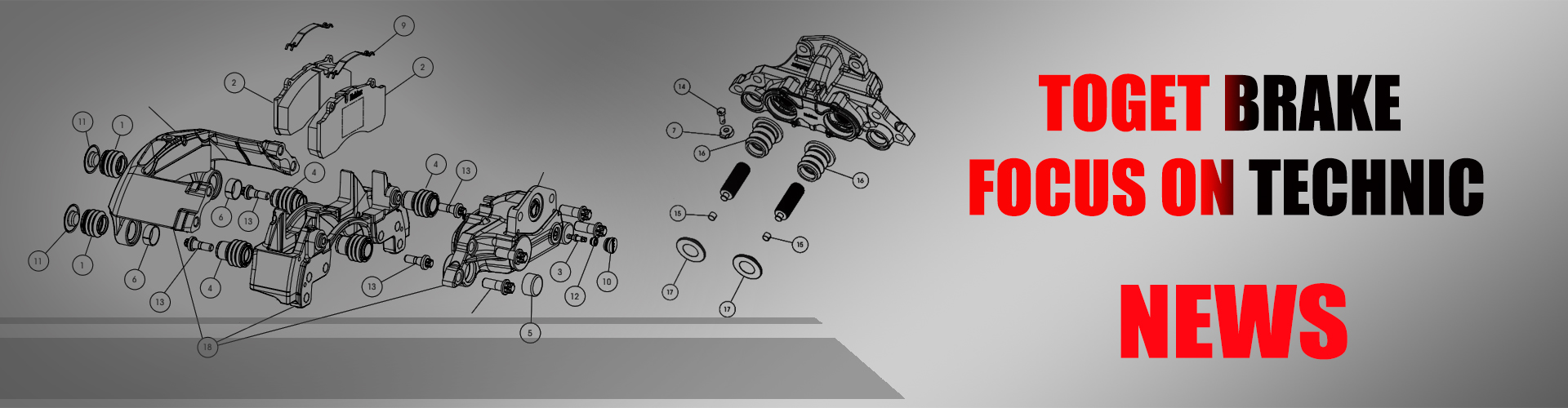

A recent trend in the industry is to specify and build newer commercial vehicles with air disc brakes. Commercial air disc brakes are quite different from the more well-known s-cam (or drum brakes) that have been quite common in North America for many years. Air disc brakes, while offering advantages to the fleet operator, also present unique difficulties and challenges when it comes to inspection and maintenance of these brake systems. Below are two illustrations showing a typical scam (drum), and a typical air disc application for modern commercial vehicles.

On the left you see a typical s-cam (drum) application that includes a brake chamber with an exposed pushrod, an automatic brake adjuster (ABA), a s-cam tube and bushings, cam rollers, linings and a drum. In this application, all parts are basically “exposed” which allows the fleet operator to visually check and inspect s-cam equipped vehicles using standard industry inspection criteria as defined by CDL requirements. Major component malfunctions can be checked and inspected visually by placing the vehicle on a lift and actuating the brakes, or through the use of electronic brake monitoring. CVSA has standard procedures for checking brake function and stroke for these applications.

On the right you see a typical air disc application that includes a brake chamber with a fully enclosed pushrod, a brake caliper with an internal adjuster mechanism, a rotor, and brake pads. This type of braking system poses unique challenges to the fleet in terms of visual brake inspections. There is no exposed pushrod in order to check chamber stroke, and the internal adjuster mechanism (designed to keep pad clearance constant like an ABA on s-cam systems), is fully enclosed, sealed, and not possible to visually inspect. In addition, the pads and outboard rotor face are nearly hidden from view making it difficult to check pads or rotor conditions visually, without wheel removal for subsequent detailed inspections. The industry has long known that a visual inspection of air disc brakes for proper operation is impractical, and this has been acknowledged by CVSA as a serious concern. The most common visually inspection method employed is simply to “check the rotor for rust” which would indicate the brake is inoperative (can require wheel removal). Thus with air disc brakes the fleet operator does not truly know with a visual inspection any of the following:

The brake actuator ( or brake chamber) is operative

The caliper internal adjuster is operative and maintaining pad clearance under all conditions

The wheel end is providing full braking, partial braking, or no braking

The brake actuator (or brake chamber) stroke is within acceptable operating limits

The brake is lightly dragging (warning of other serious problems)

Leave words, your message replied in 24hours.

Toget Brake

Brand Vision:"to become the China leading supplier of active vehicle safety systems within the commercial vehicle industry."

At Toget, focus on air disc brake calipers technics, exceeding industry standards is a strict requirement.

Brand names, original numbers, vehicle mark and models are only for reference purposes.