Remanufactured AIR DISC BRAKE CALIPERS

Heavy Duty Air Disc Brake Calipers are engineered and remanufactured to meet the high demands of fleet applications. Each unit is completely disassembled, cleaned, inspected and rebuilt with 90% brand new components to match O.E. performance standards. As an added benefit, every caliper is powder coated to extend product life and prevent rust formation.

• As much as 90% new parts

• As much as 90% new parts

• Outfitted with proprietary grease to prolong caliper life

• All new and renewed components are manufactured to O.E. performance standards

• End of line actuation test on internal clutch chain lever bridge bearings

• Guide pins and bushings tested for slide

• Components are torqued to O.E. specifications for proper long-term function

• Periodic service intervals should include: inspecting caliper slide function regularly for signs of hang up and inspecting for damaged caliper boots and tappets, depending on caliper design. The general appearance of covers, caps, hoses and brake exterior should also be examined during this time.

• For calipers with serviceable guide pins, apply grease during preventive maintenance cycles and check for caliper hang up.

• Rotors should be inspected periodically for cracking, scoring or pitting due to their exposed position. Rotors can be damaged by sand and grit from off-road and winter road conditions.

• Check for even wear on both pads. If binding occurs or there is evidence of uneven clearance or pad wear, a wheels-off inspection should be made.

• Brake pads must be replaced on both ends of an axle.

• The wear indicator on the pad assembly should be inspected every four months or four to five times between pad changes on fleet vehicles.

• If the vehicle is equipped with optional electrical wear indicators, a dash light will illuminate or an alarm buzzer will sound to indicate a brake problem.

• Vehicles utilized for extreme duty should be inspected regularly at first so the interval between inspections and pad changes can be established.

• The running clearance between the ADB caliper pads and rotor should be checked at the interval specified by brake pad manufacturer.

What advantages do Air Disc Brake (ADB) calipers have compared to drum brakes?

• ADB calipers generate much shorter stops under the same loads and speeds when compared to drum brakes. ADB calipers enhance braking capability and increase safety. The brake pads may last twice as long as drum linings in most cases. ADB calipers also have a sealed design with an integrated automatic brake adjuster for optimal performance. This design also allows for easy access to the brake pads for a significantly

quicker installation.

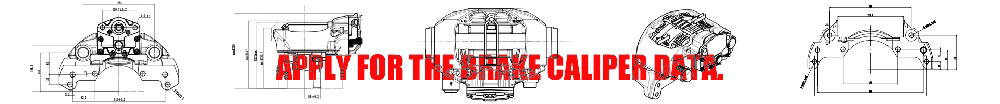

How many types of ADB calipers are there?

• There are two ADB caliper designs. The first type is a sliding caliper with an integral brake actuator. This consists of a brake actuator that moves an eccentrically supported lever which transmits the force to the brake pads through a bridge with a threaded spindle on the end of the piston. The second type is a floating caliper. This design consists of a main body which includes the actuating and adjustment mechanisms and a brake carrier which enables the caliper to slide while holding the brake pads and transferring the load that is exerted during brake application to the axle.

How often should the ADB caliper pads be checked?

• Most manufacturers recommend a visual brake pad wear inspection every three months or 20,000 miles. A more thorough inspection is recommended at six months or 50,000 miles. Refer to the service intervals stated by the caliper original equipment manufacturer.

What is acceptable wear on the rotor face?

• Most rotor manufacturers state that small radial cracks, no more than 1.5 mm wide and 1 mm deep are acceptable provided the cracks don’t extend across more than 75 percent of the disc face. A rotor with cracks that extend to either edge of the rotor should be replaced. Grooves are acceptable as long as the groove is no deeper than 1.5 mm. Refer to the rotor manufacturer for exact specifications.

Is there a need to remove the wheels for inspection?

• For most applications there is no need to remove the wheels. Inspection can be done by checking the wear indicators on the brake caliper with a flashlight.

Leave words, your message replied in 24hours.

Toget Brake

Brand Vision:"to become the China leading supplier of active vehicle safety systems within the commercial vehicle industry."

At Toget, focus on air disc brake calipers technics, exceeding industry standards is a strict requirement.

Brand names, original numbers, vehicle mark and models are only for reference purposes.